Chapter 1: Introduction to Fluid Power

This page provides the introductory chapter on fluid power from the U.S. Navy's fluid power training course, NAVEDTRA 14105A, "Fluid Power," Naval Education and Training Professional Development and Technology Center, July 2015.

Other related chapters from the Navy's fluid power training course can be seen to the right.

Introduction to Fluid Power

Fluid power is a term that describes the generation, control, and application of smooth, effective power of pumped or compressed fluids (either liquids or gases) to provide force and motion to mechanisms. This force and motion may be in the form of pushing, pulling, rotating, regulating, or driving. Fluid power includes hydraulics and pneumatics, which involve liquids and gases, respectively.

Learing Objectives

When you have completed this chapter, you will be able to do the following:

- Recognize fundamentals of fluid power.

- Explain the concept and history of hydraulics and pneumatics.

- Identify the states of matter and the factors affecting them.

Fluid Power

Advantages of Fluid Power

The extensive use of hydraulics and pneumatics to transmit power is due to the fact that properly constructed fluid power systems possess a number of favorable characteristics. They eliminate the need for complicated systems of gears, cams, and levers. Motion can be transmitted without the slack inherent in the use of solid machine parts. The fluids used are not subject to breakage as are mechanical parts, and the mechanisms are not subjected to great wear.

The different parts of a fluid power system can be conveniently located at widely separated points because the forces generated are rapidly transmitted over considerable distances with small loss. These forces can be conveyed up and down or around corners with small loss in efficiency and without complicated mechanisms. Very large forces can be controlled by much smaller ones and can be transmitted through comparatively small lines and orifices.

If the system is well adapted to the work it is required to perform, and if it is not misused, it can provide smooth, flexible, uniform action without vibration, and is unaffected by variation of load. In case of an overload, an automatic release of pressure can be guaranteed so that the system is protected against breakdown or strain. Fluid power systems can provide widely variable motions in both rotary and straight-line transmission of power. The need for control by hand can be minimized. In addition, fluid power systems are economical to operate.

The question may arise as to why hydraulics is used in some applications and pneumatics in others. Many factors are considered by the user and/or the manufacturer to determine which type of system to use in a specific application. There are no hard and fast rules to follow; however, past experience has provided some sound ideas that are usually considered when such decisions are made. If the application requires speed, a medium amount of pressure, and only fairly accurate control, a pneumatic system may be used. If the application requires only a medium amount of pressure and more accurate control, a combination of hydraulics and pneumatics may be used. If the application requires a great amount of pressure and/or extremely accurate control, a hydraulic system should be used.

Special Problems

The extreme flexibility of fluid power elements presents a number of problems. Because fluids have no shape of their own, they must be positively confined throughout the entire system. Special consideration must be given to the structural integrity of the parts of a fluid power system. Strong pipes and containers must be provided. Leaks, which are a serious problem with the high pressure obtained in many fluid power installations, must be prevented.

The operation of the system involves constant movement of the fluid within the lines and components. This movement causes friction within the fluid itself and against the containing surfaces, which, if excessive, can lead to serious losses in efficiency. Foreign matter must not be allowed to accumulate in the system, where it will clog small passages or score closely fitted parts. Chemical action may cause corrosion. Anyone working with fluid power systems must know how a fluid power system and its components operate, in terms of both the general principles common to all physical mechanisms and of the peculiarities of the particular arrangement at hand.

Hydraulics

The word hydraulics is based on the Greek word for water, and originally covered the study of the physical behavior of water at rest and in motion. Use has broadened its meaning to include the behavior of all liquids, although it is primarily concerned with the motion of liquids.

Hydraulics includes the manner in which liquids act in tanks and pipes, deals with their properties, and explores ways to take advantage of these properties.

Development of Hydraulics

Although the modern development of hydraulics is comparatively recent, the ancients were familiar with many hydraulic principles and their applications. The Egyptians and the ancient people of Persia, India, and China conveyed water along channels for irrigation and domestic purposes, using dams and sluice gates to control the flow. The ancient Cretans had an elaborate plumbing system. Archimedes studied the laws of floating and submerged bodies. The Romans constructed aqueducts to carry water to their cities.

After the breakup of the ancient world, there were few new developments for many centuries. Then, over a comparatively short period, beginning near the end of the 17th century, Italian physicist Evangelista Torricelle, French physicist Edme Mariotte, and later Swiss physicist Daniel Bernoulli conducted experiments to study the elements of force in the discharge of water through small openings in the sides of tanks and through short pipes. During the same period, Blaise Pascal, a French scientist, discovered the fundamental law for the science of hydraulics.

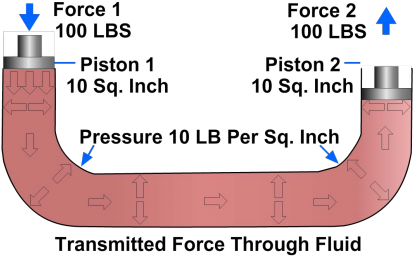

Pascal's law states that an increase in pressure on the surface of a confined fluid is transmitted undiminished throughout the confining vessel or system (Figure 1-1).

For Pascal's law to be made effective for practical applications, it was necessary to have a piston that "fit exactly." It was not until the latter part of the 18th century that methods were found to make these snugly fitted parts required in hydraulic systems. This manufacturing of parts was accomplished by the invention of machines that were used to cut and shape the necessary closely fitted parts and, particularly, by the development of gaskets and packings. Since that time, components such as valves, pumps, actuating cylinders, and motors have been developed and refined to make hydraulics one of the leading methods of transmitting power.

Use of Hydraulics

Today, hydraulic power is used to operate many different tools and mechanisms. In a garage, a mechanic raises the end of an automobile with a hydraulic jack. Dentists and barbers use hydraulic power, through a few strokes of a control lever, to lift and position their chairs to a convenient working height. Hydraulic doorstops keep heavy doors from slamming. Hydraulic brakes have been standard equipment on automobiles since the 1930s. Most automobiles are equipped with automatic transmissions that are hydraulically operated. Power steering is another application of hydraulic power. Construction workers depend upon hydraulic power for the operation of various components of their equipment. For example, the blade of a bulldozer is normally operated by hydraulic power.

During the period preceding World War II, the Navy began to apply hydraulics to naval mechanisms extensively. Since then, naval applications have increased to the point where many ingenious hydraulic devices are used in the solution of problems of gunnery, aeronautics, and navigation. Aboard ship, hydraulic power is used to operate such equipment as anchor windlasses, cranes, steering gear, remote control devices, and power drives for elevating and training guns and rocket launchers. Elevators on aircraft carriers use hydraulic power to transfer aircraft from the hangar deck to the flight deck and vice versa.

Hydraulics and pneumatics are combined for some applications. This combination is referred to as hydropneumatics. An example of this combination is equipment and machinery associated with underway replenishment (UNREP) systems and aircraft elevator systems. Air pressure is applied to the surface of hydraulic fluid in a reservoir. The air pressure forces the hydraulic fluid to raise the lift.

States of Matter

The material that makes up the universe is known as matter. Matter is defined as any substance that occupies space and has weight.

Matter exists in three states: solid, liquid, and gas; each has distinguishing characteristics. Solids have a definite volume and a definite shape; liquids have a definite volume but take the shape of their containing vessels; gases have neither a definite shape nor a definite volume. Gases not only take the shape of the containing vessel but also expand and fill the vessel, regardless of its volume. Examples of the states of matter are iron, water, and air.

Matter can change from one state to another. Water is a good example. At high temperatures it is in the gaseous state known as steam. At moderate temperatures it is a liquid, and at low temperatures it becomes ice, which is definitely a solid state. In this example, the temperature is the dominant factor in determining the state the substance assumes.

Pressure is another important factor that will effect changes in the state of matter. At pressures lower than atmospheric pressure, water will boil and thus change into steam at temperatures lower than 212 degrees Fahrenheit (°F). Pressure is also a critical factor in changing some gases to liquids or solids. Normally, when pressure and chilling are both applied to a gas, the gas assumes a liquid state. Liquid air, which is a mixture of oxygen and nitrogen, is produced in this manner.

In the study of fluid power, we are concerned primarily with the properties and characteristics of liquids and gases. However, you should keep in mind that the properties of solids also affect the characteristics of liquids and gases. The lines and components, which are solids, enclose and control the liquid or gas in their respective systems.

PDH Classroom offers a continuing education course based on this introduction to fluid power reference page. This course can be used to fulfill PDH credit requirements for maintaining your PE license.

Now that you've read this reference page, earn credit for it!