Column Analysis - Constants for Straight Line Equation

This page provides constants for the straight line equation, as used in the analysis of short columns. These constants are taken from the "Stress Analysis Manual," Air Force Flight Dynamics Laboratory, October 1986. The straight line equation for the analysis of short columns is described here.

Other related chapters from the Air Force "Stress Analysis Manual" can be seen to the right.

Column Analysis

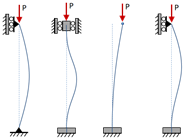

- Analysis of Simple Columns

- Column Data

- Constants for Straight Line Equation

- Crippling of Columns

- Analysis of Complex Columns

| Alloy and Temper | Thickness, in. | \(N\) (ksi) | \(M\) (ksi) | \(\left({L'\over \rho}\right)_{cr}\) |

|---|---|---|---|---|

| 2014-O | All | 9.9 | 0.037 | 160 |

| 2014-T4 | All | 35.2 | 0.251 | 89 |

| 2014-T6 | Up thru 0.499 | 61.4 | 0.410 | 50 |

| 2014-T6 | 0.500-0.749 | 67.3 | 0.471 | 48 |

| 2014-T6 | 0.750 and over | |||

| Area 25 sq in. max. | 69.7 | 0.496 | 47 | |

| Area 25 to 32 sq in. | 67.3 | 0.471 | 48 | |

| 2024-O | All | 9.9 | 0.037 | 160 |

| 2024-T4 | Up thru 0.249 | 43.6 | 0.300 | 65 |

| 2024-T4 | 0.250-0.749 | 44.8 | 0.313 | 64 |

| 2024-T4 | 0.750-1.499 | 50.9 | 0.379 | 60 |

| 2024-T4 | 1.500-2.999 | |||

| Area 25 sq in. max. | 58.4 | 0.466 | 56 | |

| 2024-T4 |

3.000 and over Area 25 sq in. max. |

58.4 | 0.466 | 56 |

| 2024-T4 |

1.500 and over Area 25 thru 32 sq in. |

53.4 | 0.407 | 59 |

| 3003-O | All | 5.4 | 0.015 | 222 |

| 3003-H112 | All | 5.4 | 0.015 | 222 |

| 5454-O | Up to 5.000 | 13.3 | 0.058 | 142 |

| 5454-H112 | Up to 5.000 | 13.3 | 0.058 | 142 |

| 5454-H311 | Up to 5.000 | 20.4 | 0.111 | 121 |

| 5456-O | Up to 5.000 (Note 3) | 21.6 | 0.120 | 111 |

| 5456-H112 | Up to 5.000 (Note 3) | 21.6 | 0.120 | 111 |

| 5456-H311 | Up to 5.000 (Note 3) | 25.3 | 0.153 | 106 |

| 6061-O | All | 5.4 | 0.015 | 222 |

| 6061-T4 | All | 15.7 | 0.074 | 128 |

| 6061-T6 | All | 38.3 | 0.202 | 63 |

| 6061-T62 | All | 28.1 | 0.127 | 74 |

| 6062-O | All | 5.4 | 0.015 | 222 |

| 6062-T4 | All | 15.7 | 0.074 | 128 |

| 6062-T6 | All | 38.3 | 0.202 | 63 |

| 6062-T62 | All | 28.1 | 0.127 | 74 |

| 6063-T42 | Up thru 0.500 | 11.0 | 0.043 | 149 |

| 6063-T5 | Up thru 0.500 | 17.5 | 0.076 | 103 |

| 6063-T6 | Up thru 0.124 | 28.0 | 0.155 | 81 |

| 6063-T6 | 0.125-0.500 | 28.0 | 0.155 | 81 |

| 7075-O | All | 13.3 | 0.058 | 142 |

| 7075-T6 | Up thru 0.249 | 79.3 | 0.602 | 44 |

| 7075-T6 | 0.250-0.499 | 87.8 | 0.859 | 46 |

| 7075-T6 | 0.500-1.499 | 87.8 | 0.859 | 46 |

| 7075-T6 | 1.500-2.499 | 81.7 | 0.629 | 43 |

| 7075-T6 | 3.000-4.499 (Note 1) | 85.2 | 0.821 | 47 |

| 7075-T6 | 3.000-4.499 (Note 2) | 79.3 | 0.602 | 44 |

| 7075-T6 | 4.500-5.000 (Note 3) | 76.9 | 0.575 | 45 |

| 7178-T6 | Up thru 0.249 | 86.5 | 0.686 | 42 |

| 7178-T6 | 0.250-2.990 (Note 3) | 88.9 | 0.714 | 42 |

| Alloy and Temper | Thickness, in. | \(N\) (ksi) | \(M\) (ksi) | \(\left({L'\over \rho}\right)_{cr}\) |

|---|---|---|---|---|

| EC-O | All | 3.2 | 0.006 | 241 |

| EC-H12 | Up to 1 in. | 8.7 | 0.030 | 165 |

| EC-H13 | Up to 1 in. | 13.3 | 0.058 | 142 |

| EC-H17 | Up to 1/2 in. | 16.8 | 0.082 | 124 |

| 1100-O | All | 4.3 | 0.010 | 221 |

| 1100-F | 0.375 and over | 7.6 | 0.025 | 186 |

| 2011-T3 | 0.125-1.500 | 45.4 | 0.368 | 79 |

| 2011-T3 | 1.501-2.000 | 40.3 | 0.308 | 85 |

| 2011-T3 | 2.001-3.000 | 35.2 | 0.251 | 89 |

| 2011-T8 | 0.125-3.250 | 48.0 | 0.400 | 77 |

| 2014-O | Up thru 8.000 | 9.9 | 0.037 | 160 |

| 2014-T4 | Up thru 6.750 | 37.7 | 0.278 | 86 |

| 2014-T6 | Up thru 6.750 | 64.7 | 0.543 | 54 |

| 2017-O | Up thru 8.000 | 9.9 | 0.037 | 160 |

| 2017-T4 | Up thru 8.000 | 37.7 | 0.278 | 86 |

| 2024-O | Up thru 8.000 | 9.9 | 0.037 | 160 |

| 2024-T4 | Up thru 6.500 | 48.0 | 0.400 | 77 |

| 3003-O | All | 5.4 | 0.015 | 222 |

| 3003-H12 | Up thru 0.374 | 12.2 | 0.051 | 148 |

| 3003-H14 | Up thru 0.313 | 16.8 | 0.082 | 124 |

| 3003-H16 | Up thru 0.250 | 22.8 | 0.131 | 112 |

| 3003-H18 | Up thru 0.204 | 26.5 | 0.164 | 103 |

| 5052-O | All | 11.0 | 0.043 | 149 |

| 5052-F | 0.375 and over | 12.2 | 0.051 | 148 |

| 6061-O | Up thru 8.000 | 5.4 | 0.015 | 222 |

| 6061-T4 | Up thru 8.000 | 18.0 | 0.092 | 128 |

| 6061-T6 | Up thru 8.000 | 38.3 | 0.202 | 63 |

| 7075-O | Up thru 8.000 | 12.2 | 0.051 | 148 |

| 7075-T6 | Up thru 4.000 | 78.7 | 0.729 | 49 |

| Alloy and Temper | Thickness, in. | \(N\) (ksi) | \(M\) (ksi) | \(\left({L'\over \rho}\right)_{cr}\) |

|---|---|---|---|---|

| 2014-O | All | 9.9 | 0.037 | 160 |

| 2014-T4 | All | 35.2 | 0.251 | 89 |

| 2014-T6 | All | 64.7 | 0.543 | 54 |

| 5456-O | All | 21.6 | 0.120 | 111 |

| 5456-H112 | All | 21.6 | 0.120 | 111 |

| 5456-H311 | All | 25.3 | 0.153 | 106 |

| 6061-O | All | 5.4 | 0.015 | 222 |

| 6061-T4 | All | 15.7 | 0.074 | 128 |

| 6061-T6 | All | 38.3 | 0.202 | 63 |

| 6061-T62 | All | 28.1 | 0.127 | 74 |

| 6062-O | All | 5.4 | 0.015 | 222 |

| 6062-T4 | All | 15.7 | 0.074 | 128 |

| 6062-T6 | All | 38.3 | 0.202 | 63 |

| Alloy and Temper | Thickness, in. | \(N\) (ksi) | \(M\) (ksi) | \(\left({L'\over \rho}\right)_{cr}\) |

|---|---|---|---|---|

| 1100-F | Up to 4 in. | 4.3 | 0.010 | 221 |

| 2014-T4 | Up to 4 in. | 35.2 | 0.251 | 89 |

| 2014-T6 | Up to 4 in. | 61.4 | 0.410 | 50 |

| 2018-T61 | Up to 4 in. | 48.0 | 0.400 | 77 |

| 2018-T61 | Up to 4 in. | 48.0 | 0.400 | 77 |

| 2018-T72 | Up to 4 in. | 33.9 | 0.237 | 91 |

| 3003-O | All | 5.4 | 0.015 | 222 |

| 3003-F | All | 5.4 | 0.015 | 222 |

| 4032-T6 | Up to 4 in. | 50.6 | 0.433 | 75 |

| 6061-T6 | Up to 4 in. | 38.3 | 0.202 | 63 |

| 6151-T6 | Up to 4 in. | 40.6 | 0.220 | 61 |

| 7075-T6 | Up to 3 in. | 73.3 | 0.535 | 46 |

| 7079-T6 | Up to 6 in. | 72.1 | 0.522 | 46 |

| Alloy and Temper | Thickness, in. | \(N\) (ksi) | \(M\) (ksi) | \(\left({L'\over \rho}\right)_{cr}\) |

|---|---|---|---|---|

| 2024-O | All | 8.7 | 0.030 | 165 |

| 2024-T3 | 0.018-0.500 | 50.6 | 0.433 | 75 |

| 3003-O | All | 5.4 | 0.015 | 222 |

| 3003-H12 | All | 12.2 | 0.051 | 148 |

| 3003-H14 | All | 16.8 | 0.082 | 124 |

| 3003-H16 | All | 22.8 | 0.131 | 112 |

| 3003-H18 | All | 26.5 | 0.164 | 103 |

| Alclad 3003-O | 0.014-0.500 | 5.4 | 0.015 | 222 |

| Alclad 3003-H12 | 0.014-0.500 | 12.2 | 0.051 | 148 |

| Alclad 3003-H14 | 0.014-0.500 | 16.8 | 0.082 | 124 |

| Alclad 3003-H16 | 0.014-0.500 | 22.8 | 0.131 | 112 |

| Alclad 3003-H18 | 0.014-0.500 | 26.5 | 0.164 | 103 |

| 5050-O | All | 6.5 | 0.019 | 185 |

| 5050-H34 | All | 20.4 | 0.111 | 121 |

| 5050-H38 | All | 25.3 | 0.153 | 106 |

| 5052-O | All | 11.0 | 0.043 | 149 |

| 5052-H34 | All | 26.5 | 0.164 | 103 |

| 5052-H38 | All | 33.9 | 0.237 | 91 |

| 6061-O | All | 5.4 | 0.015 | 222 |

| 6061-T4 | 0.025-0.500 | 18.0 | 0.092 | 128 |

| 6061-T6 | 0.025-0.500 | 38.3 | 0.202 | 63 |

| 6062-O | All | 5.4 | 0.015 | 222 |

| 6062-T4 | 0.025-0.500 | 18.0 | 0.092 | 128 |

| 6062-T6 | 0.025-0.500 | 38.3 | 0.202 | 63 |

| 6063-T83 | All | 32.6 | 0.159 | 69 |

| 6063-T831 | All | 27.0 | 0.120 | 75 |

| 6063-T832 | All | 38.3 | 0.202 | 63 |

| Alloy and Temper | Thickness, in. | \(N\) (ksi) | \(M\) (ksi) | \(\left({L'\over \rho}\right)_{cr}\) |

|---|---|---|---|---|

| 2014-O | All | 9.9 | 0.037 | 160 |

| 2014-T4 | 0.125-0.499 | 30.2 | 0.200 | 100 |

| 2014-T4 | 0.500 and over | 35.2 | 0.251 | 89 |

| 2014-T6 | 0.125-0.499 | 61.4 | 0.410 | 50 |

| 2014-T6 | 0.500-0.749 | 67.3 | 0.471 | 48 |

| 2014-T6 | 0.750 and over -- | |||

| Area 25 sq in. max. | 69.7 | 0.496 | 47 | |

| Area 25 to 32 sq in. | 67.3 | 0.471 | 48 | |

| 2024-O | All | 9.9 | 0.037 | 160 |

| 2024-T4 | 0.499 and less | 41.1 | 0.275 | 67 |

| 2024-T4 | 0.500-1.499 | 50.9 | 0.379 | 60 |

| 2024-T4 | 1.500 and over -- | |||

| Area 25 sq in. max. | 53.4 | 0.407 | 59 | |

| Area 25 to 32 sq in. | 50.9 | 0.379 | 60 | |

| 3003-O | All | 5.4 | 0.015 | 222 |

| 3003-F | All | 5.4 | 0.015 | 222 |

| 5154-O | All | 12.2 | 0.051 | 148 |

| 6061-O | All | 5.4 | 0.015 | 222 |

| 6061-T4 | All | 15.7 | 0.074 | 128 |

| 6061-T6 | All | 38.3 | 0.202 | 63 |

| 6062-O | All | 5.4 | 0.015 | 222 |

| 6062-T4 | All | 15.7 | 0.074 | 128 |

| 6062-T6 | All | 38.3 | 0.202 | 63 |

| 6063-T42 | Up to 0.500 | 11.0 | 0.043 | 149 |

| 6063-T5 | Up to 0.500 | 17.5 | 0.076 | 103 |

| 6063-T6 | Up to 0.500 | 28.0 | 0.155 | 81 |

| 7075-O | All | 13.3 | 0.058 | 142 |

| 7075-T6 | Up to 0.249 | 79.3 | 0.602 | 44 |

| 7075-T6 | 0.250-2.999 | 81.7 | 0.629 | 43 |

| 7178-T6 | Up to 0.249 | 86.5 | 0.686 | 42 |

| 7178-T6 | 0.250-2.999 | 88.9 | 0.714 | 42 |

| Alloy and Temper | Thickness, in. | \(N\) (ksi) | \(M\) (ksi) | \(\left({L'\over \rho}\right)_{cr}\) |

|---|---|---|---|---|

| 3003-O | All | 5.4 | 0.015 | 222 |

| 3003-H112 | 1 in. and over | 6.5 | 0.019 | 185 |

| 3003-H18 | Under 1 in. size | 26.5 | 0.164 | 103 |

| 3003-F | 1 in. and over | 5.4 | 0.015 | 222 |

| 6061-T6 | Under 1 in. size | 38.3 | 0.202 | 63 |

| 6061-T6 | 1 in. and over | 38.3 | 0.202 | 63 |

| 6063-T5 | All | 17.5 | 0.076 | 103 |

| 6063-T6 | All | 28.0 | 0.155 | 81 |

| 6063-T832 | All | 38.3 | 0.202 | 63 |

| Alloy and Temper | Thickness, in. | \(N\) (ksi) | \(M\) (ksi) | \(\left({L'\over \rho}\right)_{cr}\) |

|---|---|---|---|---|

| 43-F | The values to the right are based on tests of standard specimens individually cast. | 7.6 | 0.025 | 186 |

| 122-T61 | 35.2 | 0.251 | 89 | |

| 142-T21 | 15.7 | 0.074 | 128 | |

| 142-T571 | 35.2 | 0.251 | 89 | |

| 142-T77 | 18.0 | 0.092 | 128 | |

| 195-T4 | 15.7 | 0.074 | 128 | |

| 195-T6 | 24.0 | 0.141 | 107 | |

| 195-T62 | 33.9 | 0.237 | 91 | |

| 195-T7 | 19.2 | 0.101 | 120 | |

| 214-F | 11.0 | 0.043 | 149 | |

| B214-F | 12.2 | 0.051 | 148 | |

| F214-F | 11.0 | 0.043 | 149 | |

| 220-T4 | 15.9 | 0.076 | 131 | |

| 319-F | 11.5 | 0.047 | 163 | |

| 319-T6 | 14.4 | 0.065 | 134 | |

| 355-T51 | 12.2 | 0.051 | 148 | |

| 355-T6 | 14.4 | 0.065 | 134 | |

| 355-T61 | 23.4 | 0.136 | 109 | |

| 355-T7 | 24.2 | 0.143 | 107 | |

| 355-T71 | 15.9 | 0.076 | 131 | |

| 356-T51 | 11.5 | 0.047 | 163 | |

| 356-T6 | 13.7 | 0.061 | 144 | |

| 356-T7 | 18.8 | 0.098 | 123 | |

| 356-T71 | 13.0 | 0.056 | 143 | |

| A612-F | 14.4 | 0.065 | 134 |

| Alloy and Temper | Thickness, in. | \(N\) (ksi) | \(M\) (ksi) | \(\left({L'\over \rho}\right)_{cr}\) |

|---|---|---|---|---|

| 43-F | The values to the right are based on tests of standard specimens individually cast. | 7.6 | 0.025 | 186 |

| C113-F | 24.0 | 0.141 | 107 | |

| 122-T551 | 37.7 | 0.278 | 86 | |

| 122-T65 | 35.2 | 0.251 | 89 | |

| F132-T5 | --- | --- | --- | |

| 142-T571 | 33.9 | 0.237 | 91 | |

| 142-T61 | 44.1 | 0.352 | 80 | |

| B195-T4 | 16.8 | 0.082 | 124 | |

| B195-T6 | 25.3 | 0.153 | 106 | |

| B195-T7 | 18.0 | 0.092 | 128 | |

| A214-F | 14.5 | 0.066 | 135 | |

| 333-F | 18.0 | 0.092 | 128 | |

| 333-T5 | 25.3 | 0.153 | 106 | |

| 333-T6 | 29.0 | 0.188 | 100 | |

| 333-T7 | 26.5 | 0.164 | 103 | |

| 355-T51 | 25.3 | 0.153 | 106 | |

| 355-T6 | 26.5 | 0.164 | 103 | |

| 355-T62 | 44.1 | 0.352 | 80 | |

| 355-T7 | 31.4 | 0.212 | 98 | |

| 355-T71 | 31.4 | 0.212 | 98 | |

| C355-T61 (Note 4) | 35.2 | 0.251 | 89 | |

| 356-T6 | 25.3 | 0.153 | 106 | |

| 356-T7 | 24.0 | 0.141 | 107 | |

| A356-T61 (Note 4) | 31.4 | 0.212 | 98 | |

| C612-F | 15.7 | 0.074 | 128 | |

| 750-T5 | 8.7 | 0.030 | 165 | |

| B750-T5 | --- | --- | --- |

Notes:

- Area up thru 20 sq in.

- Area 20 thru 32 sq in.

- Area up thru 30 sq in.

- The values shown for this alloy are valid for any location in the casting.